[et_pb_section][et_pb_row][et_pb_column type=”4_4″][et_pb_text admin_label=”Text” background_layout=”light” text_orientation=”justified” text_font_size=”16″ text_line_height=”1.9em” use_border_color=”off” border_color=”#ffffff” border_style=”solid”]

SensorCon One was a 4 day intensive training course/conference hosted in Salt Lake City, UT by David Myszka and Rebecca Rich of Biosensor Tools. They are both leaders in the field of label-free analysis and have been working in it since the inception of surface plasmon resonance in the 1990s. We attended this conference to gain an even deeper understanding of label-free analysis, meet others in the field, and become biosensor superheroes! Even if you are just learning about what is surface plasmon resonance, we cover the details below and share with you some of the things we learned at the conference.1. The market for biosensors is growing, and fast

Surface plasmon resonance (SPR) biosensors, and similar technologies, are becoming more and more important across a number of fields. This growth comes from a combination of new technologies and new applications. New technologies are leading to instruments that can measure weaker binding interactions and lower molecular weight compounds, while other innovations are increasing throughput and decreasing cost per data point.

Applications are growing beyond the traditional antibody and protein markets. The use of SPR for high throughput screening of drug hits is expanding the market for small molecular analysis. Also, fragment based drug discovery using surface plasmon resonance becoming more popular, also growing this sector. The use of surface plasmon resonance with crude samples is also expanding. For example, SPR is being used for early stage kinetic screening of therapeutic antibodies directly in crude media like hybridoma samples, cutting down the sample preparation time needed. Also, new high throughput instruments are being used to speed up the development time for therapeutic antibodies.

Applications for analyzing the performance of biosimilars is becoming increasingly important as a number of billion dollar a year biotherapuetics come off patent. SPR can be used to help show that the performance of biosimilars are sufficiently similar to a reference biologic, which is key for navigating regulatory requirements in an efficient manner.

This is just a small sampling of the exciting new developments in the SPR field. Overall the outlook for the surface plasmon resonance biosensor industry is very positive.

2. The trend in instrument technology is higher sensitivity, higher throughput, and higher cost

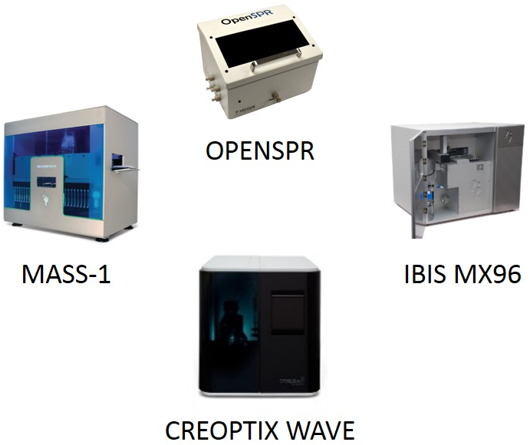

Amazing new technologies are being developed that are pushing the limits of biosensor performance further. For example, Creoptix, a Switzerland based company, uses waveguide technology to improve sensitivity for small molecules so that there is no lower limit on molecular mass. The MASS-1 by Sierra Sensors is a high throughput machine that can process over 2000 samples per day using 16 detection spots with 8 injection needles.

Wasatch Microfluidics use their continuous flow microspotter technology and the IBIS MX96 SPR imaging instrument to generate up to 10,000 sensorgrams in a single run (about 36 hours). The Prometheus from NanoTemper is a new tool for stability screening that can look at the folding and unfolding of 48 different protein or antibody samples at once. This is just a small sample of some of the new technologies out there.

However, with all of these developments, instrument cost and complexity has increased. The average cost of the instrumentation presented at Sensorcon 1 was over $200,000, with annual maintenance contracts an average of $15,000. This made it clear to us that our OpenSPR™ instrument fills an important gap in the market – the need for an affordable and low maintenance SPR solution.

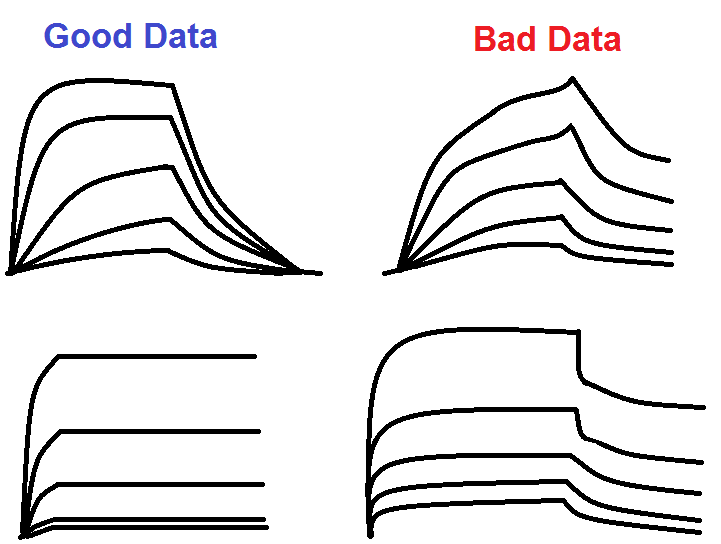

3. There is still a lot of BAD data out thereAs much as biosensor technology and know-how has progressed since the early 1990’s, there are still a lot of researchers that struggle to get good, reliable binding data that fit to a 1:1 model. Unfortunately much of this data gets published. Even expert users run into this problem all the time. However, inexperienced users will try to explain poor data fits with complex physical models rather than try to improve experimental conditions, which in most cases is not correct. Many experimental variables can be modified to improve binding data, such as using different surface chemistries, reversing which binding partner is immobilized, reducing immobilization levels, adding or removing detergents, and many other things. It is an iterative process. Researchers have to remember not to over-fit the data with complicated models that do not match reality of the biological world.